Eddy-Current Testing (ET)

Detect Volumetric Flaws & Defects

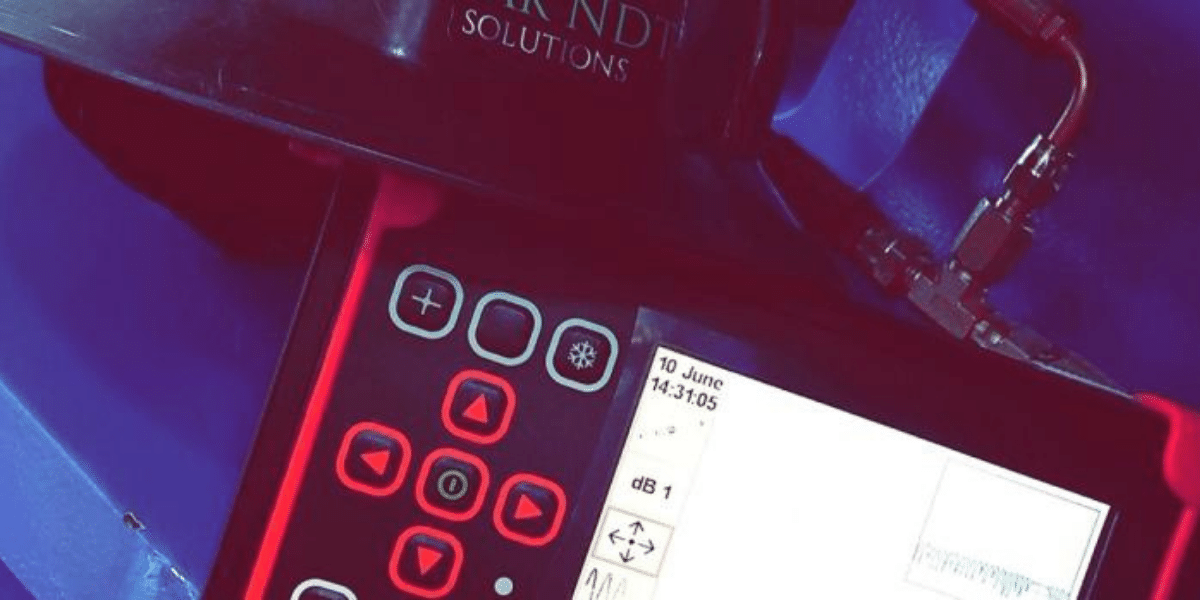

Eddy Current (ECT)

Peak NDT Solutions is at the forefront of cutting-edge nondestructive testing and provides complete ECT services for several applications. ECT is safe, effective, efficient, and can detect easily-overlooked volumetric flaws and defects such as corrosion, thickness loss, erosion, material degradation, large porosities, and cracking. Our highly experienced professionals can detect surface-breaking, near-surface, and far-surface defects.

Our ASNT Certified professionals are equipped with state-of-the-art instrumentation, flexible probes, and advanced software. At Peak NDT Solutions, we ensure our clients are provided with the highest data quality possible.

ECT has many benefits, including:

-

It is a cost-effective and reliable way to inspect tubing.

-

Inspect non-ferromagnetic tubes and materials.

-

Detection and sizing of metal discontinuities such as corrosion, erosion, tube-to-tube wear, pitting, fretting, cracks, etc.

-

Can be used to inspect condensers, feedwater heaters, air conditioners, chillers, and other heat exchangers

-

Has multi-frequency inspection with mixing and filtering capabilities.

-

Data can be recorded and archived, which allows the tracking of the corrosion rate for each tube.

Interested in Our NDT Services?

Request a free quote today and talk to one of our NDT experts to see how we can help your business.

Request a QuoteQuote Request

Please fill out the form below to request a quote. We will get back with you soon. Thank you for your patience.