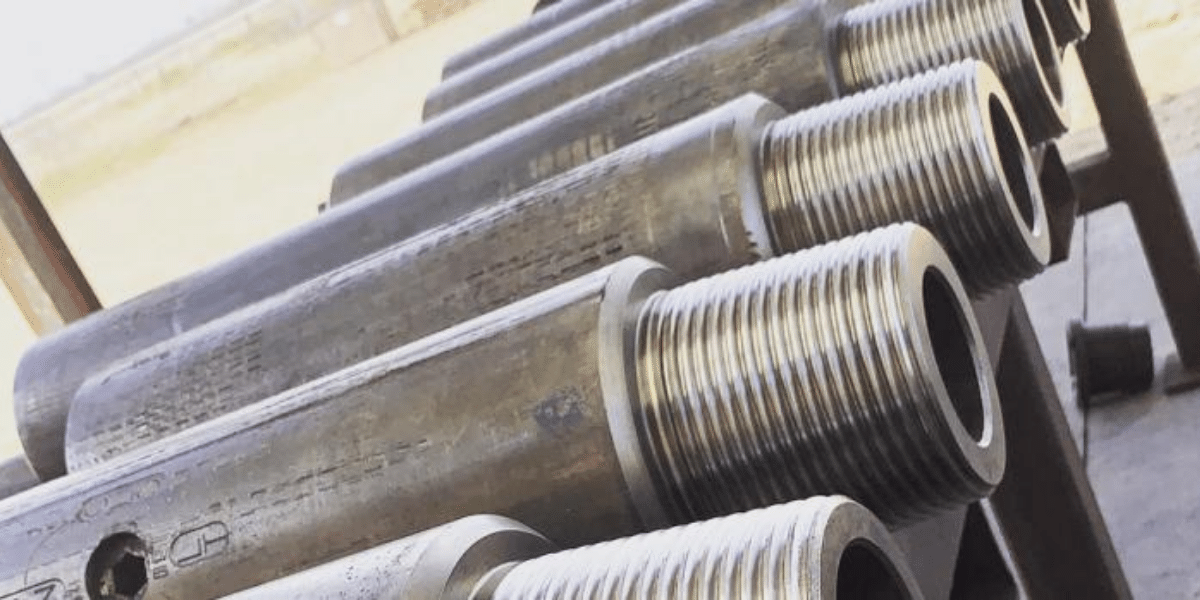

VISUAL TESTING (VT)

Quality Control

Visual Testing (VT), or visual inspection, is the oldest, most versatile, and commonly used NDT method. VT is typically the first step in the examination process to inspect a variety of product forms including castings, forgings, machined components and weld elements.

When VT is used alone or in conjunction with other test methods, qualified visual inspection is a reliable and highly cost-effective tool for quality control assurance. A visual inspection applies proper lighting, measurement, and comparative tools used by our certified technicians to ensure the designs comply and conform to drawings, codes, and specification requirements.

Visual Inspection:

-

Require little, if any, specialized equipment

-

Has few limitations and complete applications

-

Used for detection and interpretation of surface flaws

The visual testing process is performed by trained and qualified visual inspectors to apply knowledge of drawings, codes, and standards to evaluate various new and in-service equipment.

Trained VT technicians scan, measure, and detect depth, and color, to detect flaws in several applications including:

-

Design drawings and specifications conform with weld size and contour

-

Building fabrication and construction conform to specs

-

Power generation services inspections

-

Evaluate gauges and tools with comparative measurements

Interested in Our NDT Services?

Request a free quote today and talk to one of our NDT experts to see how we can help your business.

Request a QuoteQuote Request

Please fill out the form below to request a quote. We will get back with you soon. Thank you for your patience.